Advantages &

Calculation

The most cost effective production is not always the one done with the lowest total cost of parts. True savings comes from innovative and smart designed production processes. Years of working together with our customers in developing smarter production processes have given us great insight in to how to help our customer save Time, Money and Precious Space in the production. Small changes can save massive amounts of time spent and, in the end, money saved because as we all know; time is money!

Cost efficiency

Can we help you save money in your production? Introducing the Profit Calculator. Please use your own preferred size, current price and volumes to check if there are any saving for your company to make. We´re using welding nuts as the comparison in the calculation since it´s the most used part in production today. And if you like we can send you a whole simplified calculation if the result is of interest.

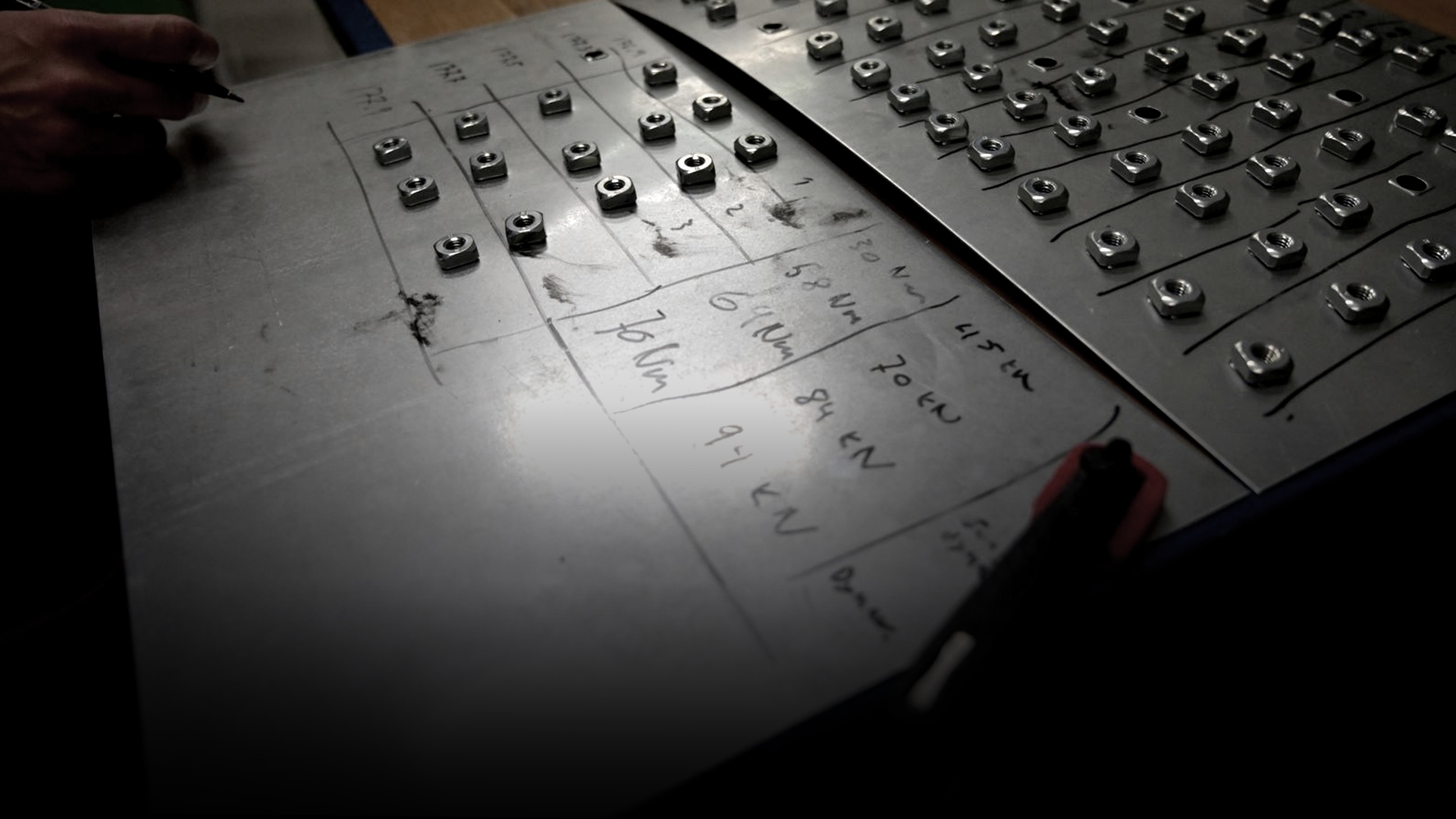

WELD VS. PIERCE

Pierce Nut is a cost-effective solution that reduces production steps, frees up space, and ensures high joint quality with 100% repeatability. It lowers energy consumption and eliminates the need for welding gases and ventilation, making it environmentally friendly.

It works with all metallic materials and is particularly beneficial for use in progressive die presses, materials unsuitable for welding, or applications with high push-out and torque-out requirements. Pierce Nut streamlines production while enhancing quality and sustainability.

Below you can read about 2 case examples of how pierce can make your production more efficient.

Small volume case: Space efficiency

Background:

Customer is planning to produce 45k plates / year in a press line. Each plate will have 2 nuts. (new item) Current weld cell is at machimum capacity so customer are looking at alternatives to avoid investing in new weld cell. The plate is a 1,5mm DC04 steel plate and the nut is a M6 nut with zinc plating.

Solution:

Installing pierce nut directly in press tooling. The plate will be finnished with nut installed from press line and there will be no need for a weld cell.

Results:

This results in a 30K / year saving by reducing process steps. Investment of 450k in pierce nut equipment was needed. Main benefit was that customer avoided needed to invest in an additional weld cell. Saving money and factory floor space.

High volume case: Cost reduction

Background:

Customer is producing 300k plates/ year with 6 weld nuts/plate (running prodcution item). Customer is looking for options for saving cost on the item.

Plate is 2mm DC01 steel plate. Nut is M8 zinc plated.

Solution:

Installing 6 M8 pierce nut with power feeder directly inte press tooling.

Results:

Cutting process steps which leads to large cost reduction. 1,6m/year saved in total. Initial investment of 600k in pierce nut equipment needed.

SEE HOW WE CALCULATED

We are glad you are interested!

Please fill in your information below and you’ll get access for downloading a calculation (Excel).

SEE HOW WE CALCULATED

We are glad you are interested!

Please fill in your information below and you’ll get access for downloading a calculation (Excel).

Thank you for Your interest!

We will get back to you as soon as possible.