MECHANICAL

JOINING SOLUTIONS

FOR FUTURE GAINS.

We help companies into the new era of fastening with innovative solutions for lightweight and mixed materials.

Technological and economic advantages

Mechanical joining in an automated assembly always offers consistent installation and by that a stable fastening joint. This does not only give economic advantages during installation but also leads to low life-time cost.

Paying attention to fasteners in the design phase enables you to reduce the range of fasteners used, which in turn free up warehouse space and reduce administration as well. Below are some of the most common benefits:

• Time efficient

• Less Equipment & Space efficient

• Consistent quality

• Material independent

• Clean & safe environment

Ser how much you would gain with our calculator:

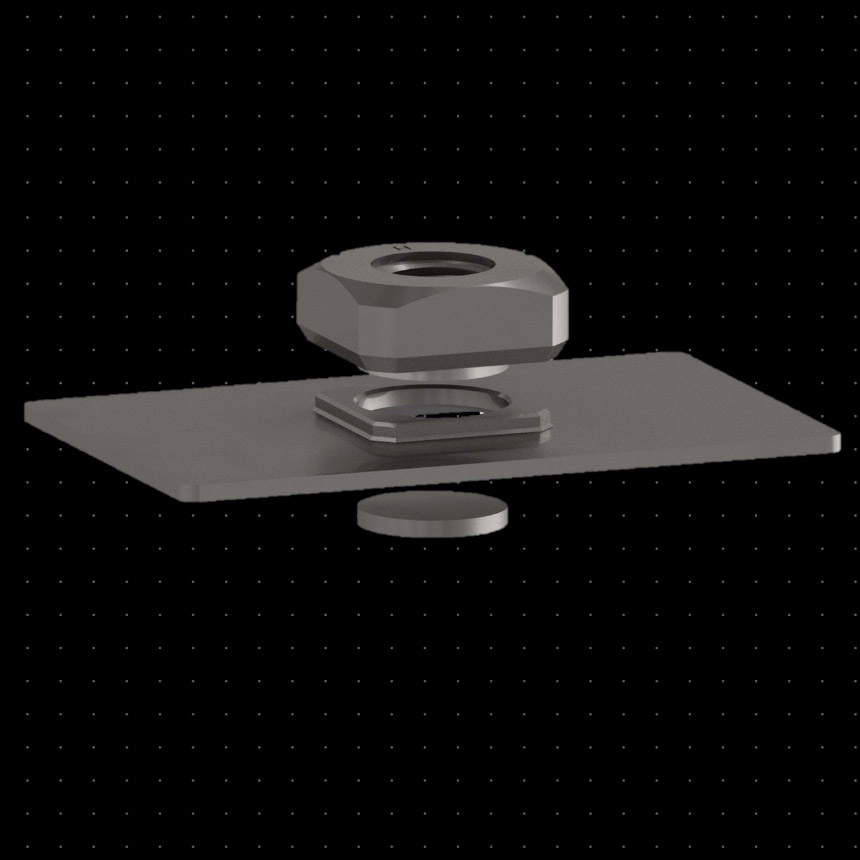

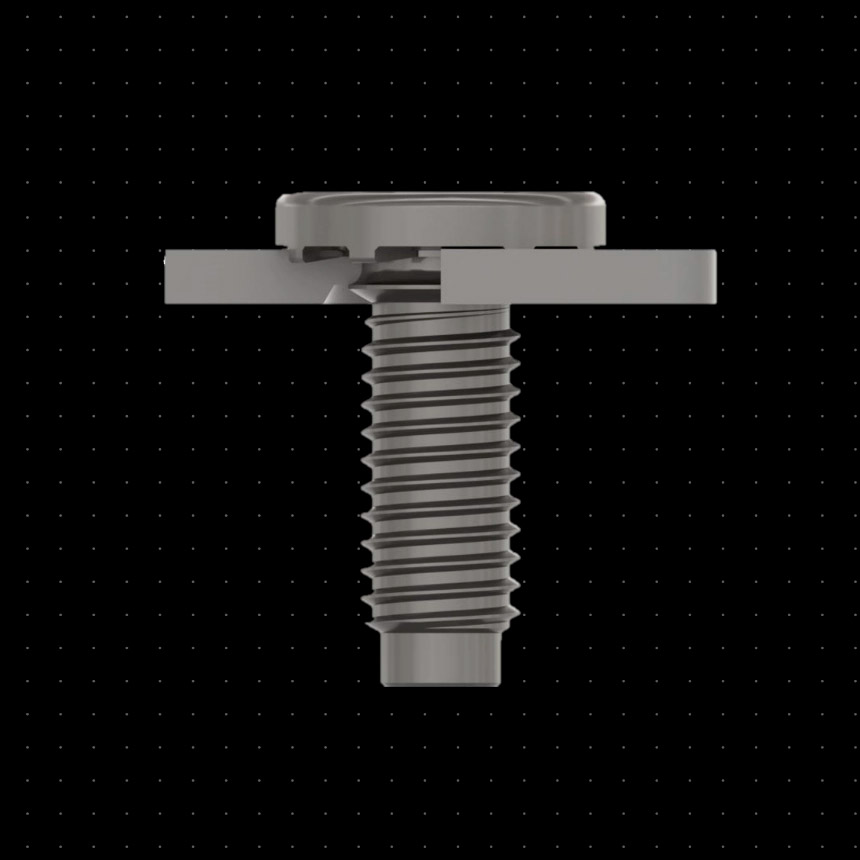

FASTENER SOLUTIONS

Materials used, forces required, corrosion resistance, friction, mating parts info. These are all examples of input needed to find a good fastener solution.

The fastener also needs to be designed for manufacturing, keeping the production steps in the fastener production low to reduce costs and guarantee an optimal solution.

Solutions by material

Materials differ from each other due to variations in their atomic structure, bonding, and chemical composition. These factors influence their properties, such as strength, hardness, conductivity, heat resistance, and flexibility. Thats why our solutions differ depending on material used.

Find the right product based on common material selection below:

object(WP_Term)#7000 (11) {

["term_id"]=>

int(19)

["name"]=>

string(5) "Steel"

["slug"]=>

string(5) "steel"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(19)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(7)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "1"

}

Steel

Steel

object(WP_Term)#2357 (11) {

["term_id"]=>

int(46)

["name"]=>

string(19) "High strength steel"

["slug"]=>

string(19) "high-strength-steel"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(46)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(2)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "4"

}

HIGH STRENGTH STEEL

HIGH STRENGTH STEEL

object(WP_Term)#7023 (11) {

["term_id"]=>

int(23)

["name"]=>

string(9) "Aluminium"

["slug"]=>

string(9) "aluminium"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(23)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(5)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "6"

}

Aluminium

Aluminium

object(WP_Term)#6988 (11) {

["term_id"]=>

int(21)

["name"]=>

string(6) "Copper"

["slug"]=>

string(6) "copper"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(21)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(5)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "7"

}

Copper

Copper

object(WP_Term)#6981 (11) {

["term_id"]=>

int(20)

["name"]=>

string(9) "Magnesium"

["slug"]=>

string(9) "magnesium"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(20)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(2)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "9"

}

Magnesium

Magnesium

object(WP_Term)#6977 (11) {

["term_id"]=>

int(22)

["name"]=>

string(9) "Composite"

["slug"]=>

string(9) "composite"

["term_group"]=>

int(0)

["term_taxonomy_id"]=>

int(22)

["taxonomy"]=>

string(8) "material"

["description"]=>

string(0) ""

["parent"]=>

int(0)

["count"]=>

int(4)

["filter"]=>

string(3) "raw"

["term_order"]=>

string(1) "8"

}

Composite

Composite

AUTOMATION SOLUTIONS

What are the prerequisites of the production site? What is the needed output when it comes to, e.g. cycle time, tolerance and installation feedback?

Our automation solution can be incorporated in a robotic production cell or installed directly in a progressive die.

Solution Development & Maintenance

Looking at the production conditions and the actual demands on the fastening joint, we find the optimal solution together with the customers.

This process usually works in several steps with onsite assessment, workshops and testing at our lab. The solution will include; Fastener, Automation and Supply.

THE PROCESS

Analysis & Assessment

- On site

- Workshops

- Studies

Framework

- KPI

- Budget

- Timeline

Concept development

- Fastening

- Assembly

- Automation

- Product supply

Prototype &

test

- Lab

- In production

- Tuning

- Validation

Implementation

- Systems installed

- Supply start

- Personell training

- Service and operation setup

Evaluation

- KPI

- Assessment

- Tuning

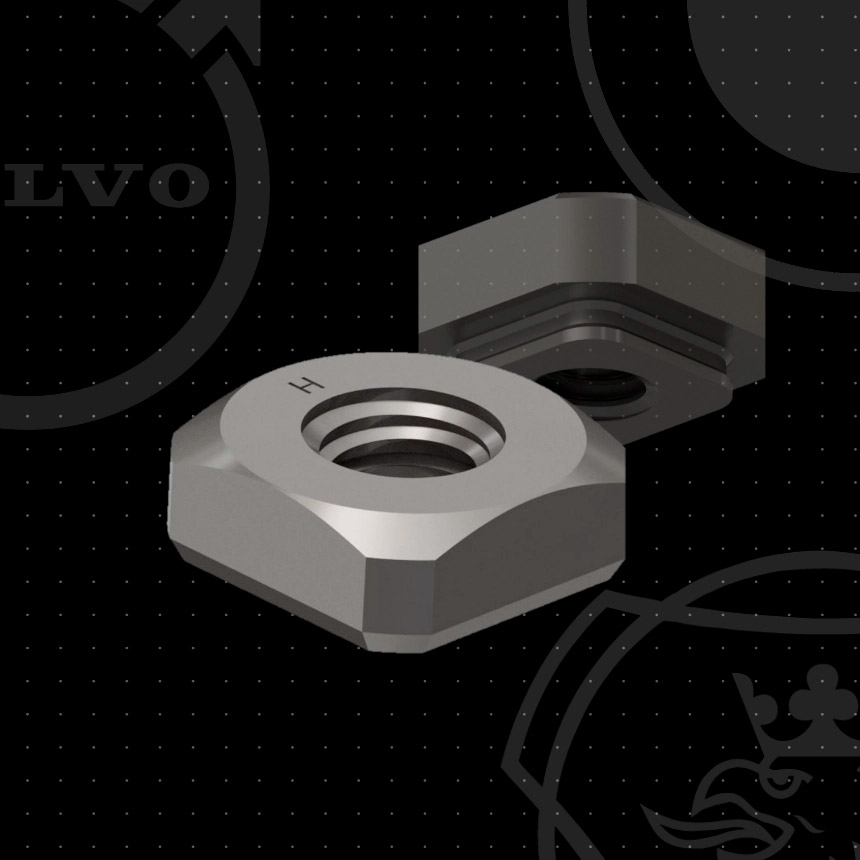

WELD VS. PIERCE

Why choose pierce instead of weld? Pierce Nut is a cost-effective solution that reduces production steps, frees up space, and ensures high joint quality with 100% repeatability. It lowers energy consumption and eliminates the need for welding gases and ventilation, making it environmentally friendly.

Read about 2 case examples of how pierce can make your production more efficient:

CONTACT

We’re glad you found us and took time to look around. Contact us at Fastit for a more detailed presentation and how we can help you with your challenges.

Best regards,

Team Fastit